Spa Heater article.

Spa Care Tips

published on the web by

Havenmade Inc.

Copyright 1997-2008

You may down-load this for your personal use. Duplicating or publishing

any

part of this document for commercial use is strictly prohibited.

Heater Problems

If there is one item on a spa that should be designed properly, it's

the

heater. We want our spa heaters to last a long time and to not cause

harm,,

either to itself or the equipment around the heater chamber, also

called

the "heater manifold". Last we want the heater to be safe.

Believe it or not, there are some modern heaters that have UL stamped

on them and are not able to fulfil all of the above criteria.

It doesn't matter how the heater is operated, either from mechanical

thermostats,

or from the most advanced circuit boards and super control systems, if

they

don't have built in safeguards, they are not going to be sold from our

store.

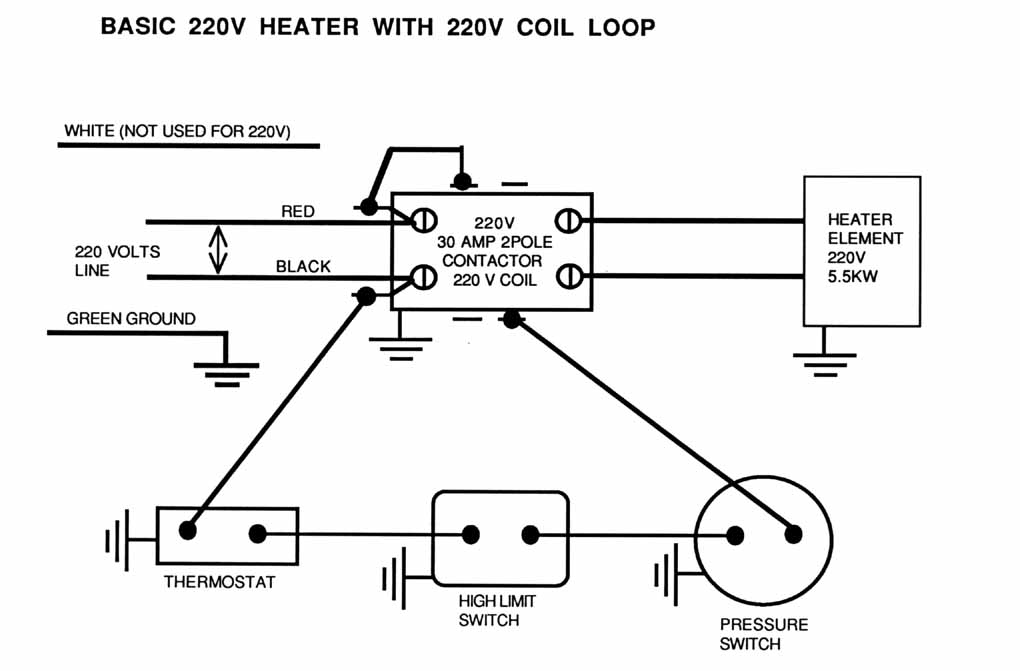

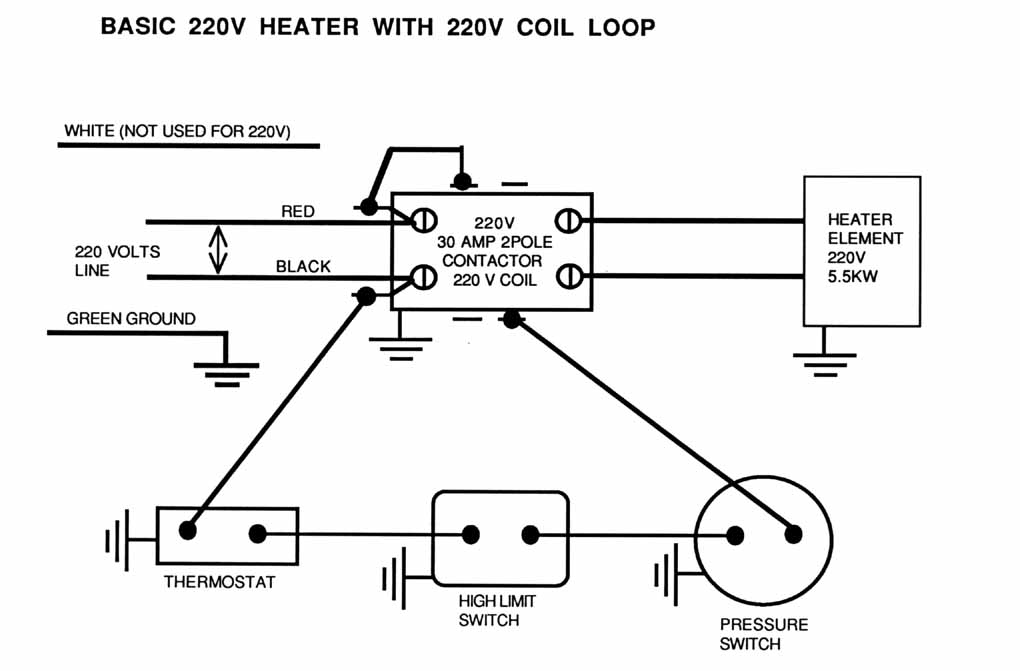

The standard heater control system, that has been around for years, and

has been proven to be as safe as possible is shown in the diagram

below. There are variations on this theme.

The above diagram is of a 220-240 volts heater circuit. You will notice

that it is made up of five components;

(1) A contactor which is the switch that actually turns on the

current

to the (2) heater element. The heater element is

similar to

the heater elements on an electric stove. It converts electricity into

heat

by electrical resistance in the heater core.

The (3) thermostat, is an on/off switch that is adjusted by

the

spa user to the desired temperature. When the temperature drops, it

switches

to "on" until the desired temperature is reached then it returns to

"switch

off". The (4) high limit switch is similar to the thermostat,

but

is set to one temperature, the highest allowable temperature (usually

121

degrees F.) before things start to melt. It usually has a reset button,

but it can also be automatic and reset itself after things cool down. I

much prefer the manual reset type, because the high limit only trips

when

something is wrong. The system should be checked before restarting. If

your high limit trips give us a call

Last, but in no way least, is the(5) pressure switch or flow

sensor.

There are two types available, one senses an increase in the water

pressure

in the heater manifold, the other type is a flow sensor, that actually

uses

a "paddle" placed in the plumbing pipe. As the water starts to move in

the

pipe, the paddle is pressed against and turns on the flow switch,

indicating

that water is moving through the heater.

The pressure type senses that there is water moving because the water

pressure in the heater manifold is higher. When the pressure reaches a

preset value, usually 1 to 2 pounds above the still water condition, it

switches to the "on"position and stays there until the pressure drops.

One thing we absolutely do not want is having the heater on with no

water flowing. Even though the "high limit" switch is there to shut

things off,

it is much better to never reach the high limit temperature.

If the heater is in a dry manifold, as during a spa water refill

before

the water flows, the high limit often will not sense the rapid change

of

the air temperature, and the heater turns bright red (just like the

electric

stove burner on high). This melts the PVC parts around the heater, or

in

the case of some with plastic heater manifolds, also melts the heater

manifold

housing.

In the above drawing, all three of the switching devices must be on

in

order for the heater contactor to switch on. This is the best scenario.

If you eliminate either the high limit or the pressure switch, the

heater

can go on and melt down the spa equipment. This is one reason why a low

flow

circ pump is a really bad idea.

Those low flow "circ" pumps, the kinds that some spas are running

24

hours per day, (presented as some sort of "clean" system,) have such

low

pressure and flow that they can't operate a pressure switch. Often the

heaters

used with these spas are not very powerful (less than 4500 watts). The

standard

is 5500 watts and every watt is needed when the weather is cold!

The tiny "circ" pumps are responsible for heater element burn-out,

heater meltdown, and a lot of wasted repair costs. I have known

customers who have reset the high limit switch several times in an

attempt to keep their spas

from freezing. They did not know the tiny pump was not working. If the

heater is turned back on several times with no water flowing, it begins

to

weaken and in some cases burns out. This really shortens the life of

heating

elements. Since customers are not technicians, when they see a "reset"

button,

they are going to press it. In this way they are unknowingly destroying

their own heater.

For proper heater operation, the heater only comes on when there is

water flowing. There must be three conditions met in order for the

heater to be turned on. 1. The thermostat is switched on telling the

system that the spa water is too cool. 2. The spa has not overheated

and "tripped" the high limit switch. And 3. There is water flowing,

thus the pressure or flow switch is

set to "on". When all conditions are met then the contactor is allowed

to

turn on the heater.

Having a "current collector" around the heater is also very

important. Spa heaters that don't have a metal shield directly around

them, are not

as safe. When spas are designed so that the nearest material to the

heater

is plastic or even a polymer, can ground out into the spa water,

instead

of grounding out to a metal shield very near the heater element.

Proper care of the heater parts.

If you want your heater to last, keep your water in balance. More times

than I care to remember I have seen heater elements that were ruined by

improper

pH and Total Alkalinity. If your heater is being ruined, just think

what

it is doing to your skin!

It doesn't matter what the heater warranty* is, if your spa water

isn't

in balance, it is not good for you!

I have also seen heater elements that were 12 to fifteen years old,

still functioning, without a spec of calcium (boiler scale) or rust. If

you just

take care of the water, your heater will last for a very long time. By

the

way, these spas all had pressure switches, and a standard modern two

speed

pump for filtering and heating.

I always recommend some sort of sequestering agent be added to the

water. This will help keep the spa shell as well as the heater free

from deposits.

If you own a spa with a tiny circ pump, we highly recommend that

you

have it removed and replaced with a more modern pump system! We also

recommend that you install a pressure switch to insure your heater life.

*Often times spa companies will try to throw a spa buyer off track by

having

a special heater warranty, or component warranty. They do this because

their shell/structure warranty is so bad. In their brochures they keep

repeating

over and over the heater warranty, so you might not notice how bad the

main structure and surface warranty is; or how quickly they freeze.

For a really detailed explanation on spas today, order the booklet "How

Spas are Made", published by the Spa Specialist Inc.

Back to index

Havenmade Inc

Broomfield, CO 80023

(303) 404-AAAH ! (2224)

If you would like to contact the author; just email at jim@spaspecialist.com